Advanced Manufacturing Precision

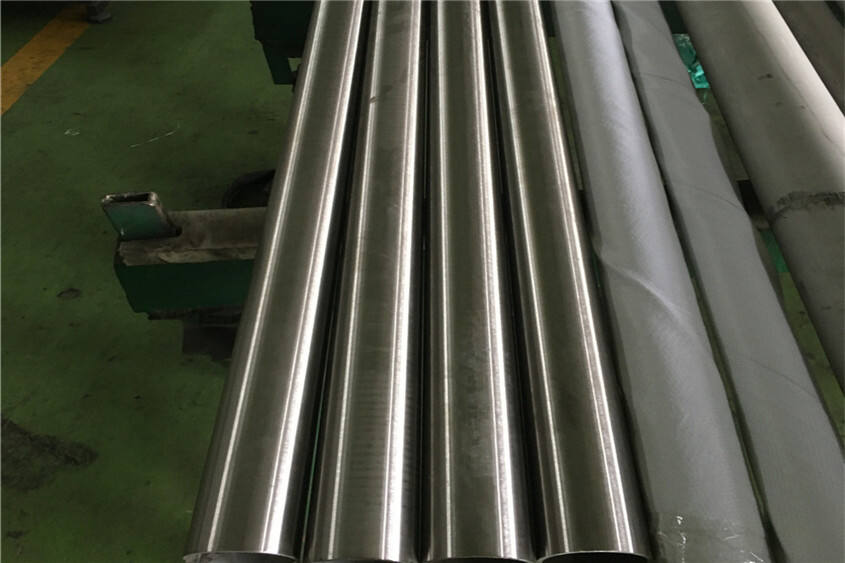

Stainless steel pipe fabrication employs cutting-edge manufacturing technologies that ensure unprecedented precision in every component produced. Computer Numerical Control (CNC) machines and automated welding systems work in perfect synchronization to maintain tight tolerances and exceptional consistency throughout the production process. This level of precision is crucial for ensuring proper fit-up during installation and optimal performance in service. Advanced quality control systems, including 3D scanning and digital measuring equipment, verify dimensional accuracy at every stage of fabrication. The precise control over wall thickness, diameter, and end preparation results in superior joint integrity and reduced potential for installation issues. This manufacturing precision not only enhances the final product quality but also contributes to reduced material waste and improved cost-effectiveness.