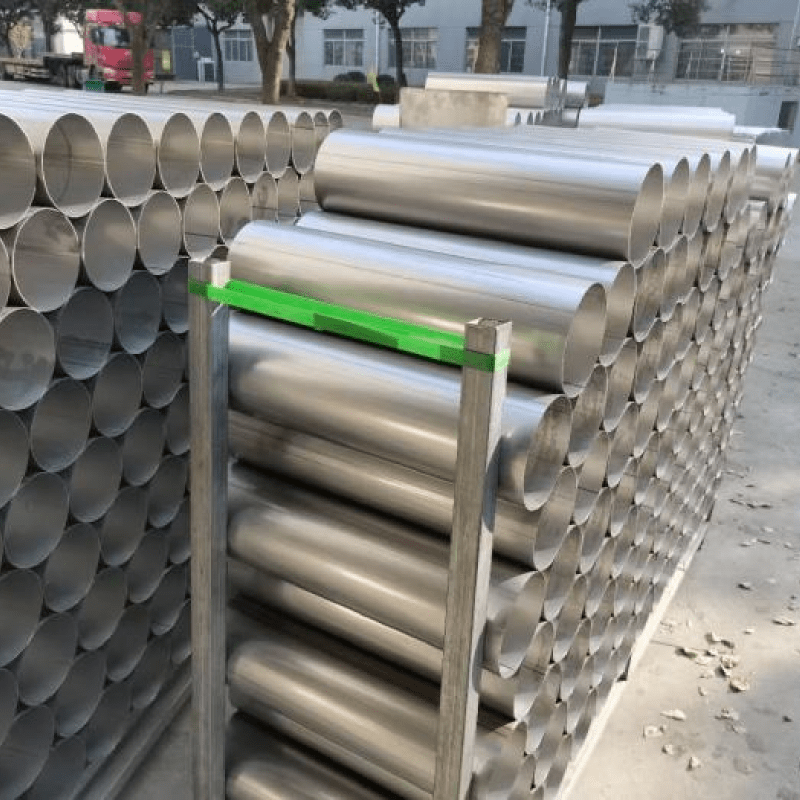

Corrosion Resistance

The corrosion resistance of the stainless steel welded tube is one of its standout features. It is particularly important in environments where exposure to chemicals, acids, or salt can cause rapid deterioration in other materials. This resistance ensures the tube maintains its structural integrity and functionality over an extended period, reducing the total cost of ownership for the customer. Whether it's in processing plants, marine applications, or chemical manufacturing, this feature is invaluable for industries that demand reliability and longevity from their materials.