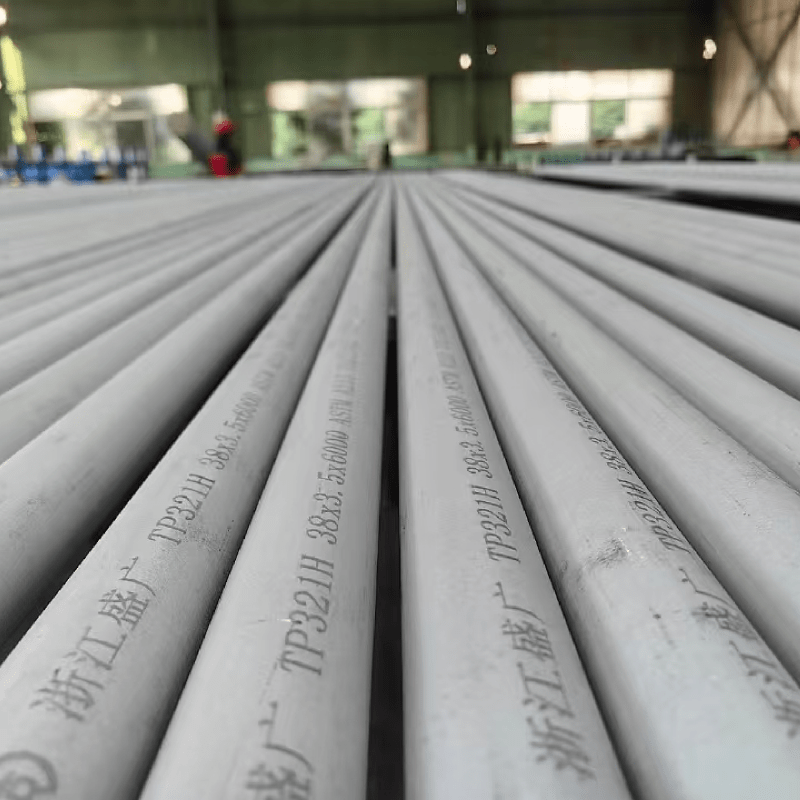

مقاومة ممتازة للتآكل والمتانة

يُعد مقاومة شديدة التآكل التي تتمتع بها شفاه الفولاذ المقاوم للصدأ سببًا رئيسيًا لتميّزها في التطبيقات الصناعية. فتركيبة الفولاذ المقاوم للصدأ العالية الجودة، والتي تتضمن عادةً الكروم والنيكل، تُشكّل طبقة سلبية تُصلح نفسها تلقائيًا وتوفر حماية مستمرة ضد مختلف العناصر المسببة للتآكل. تمتد هذه المقاومة الذاتية إلى التآكل الجوي وكذلك الهجوم الكيميائي، ما يجعل هذه الشفاه مثالية للاستخدام في البيئات القاسية. كما تتعزز متانة المادة لقدرتها على الحفاظ على السلامة الإنشائية عند درجات الحرارة والضغوط المرتفعة، مما يضمن أداءً ثابتًا طوال عمر الخدمة. وتُرجم هذه المقاومة الاستثنائية للتآكل إلى تقليل احتياجات الصيانة، وفترات خدمة أطول، وموثوقية أفضل للنظام، مما يؤدي في النهاية إلى وفورات كبيرة في التكاليف على مدى عمر التركيب.