Avanceret Fremstillingsteknologi

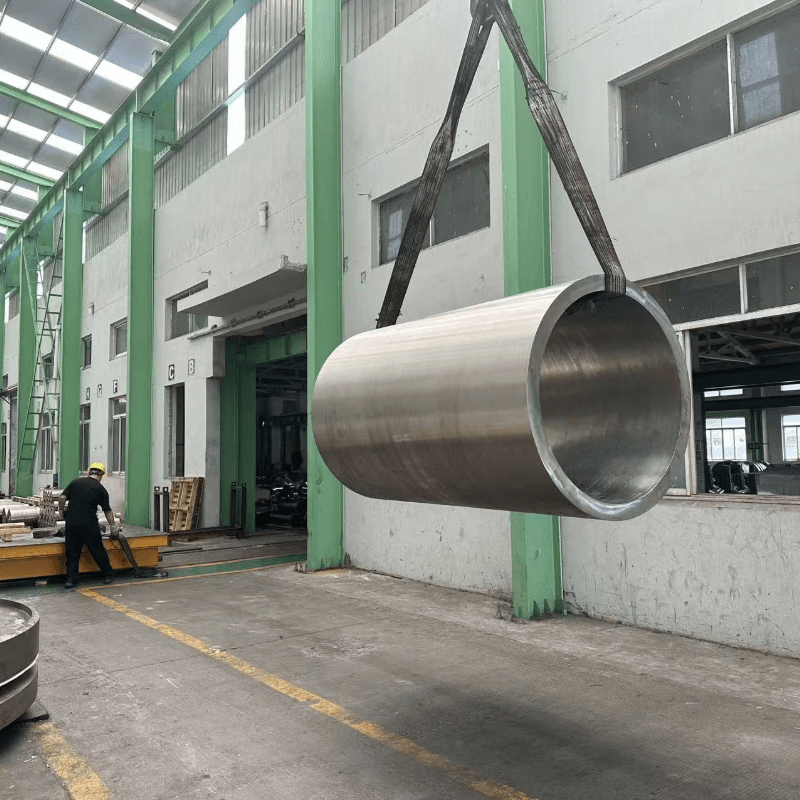

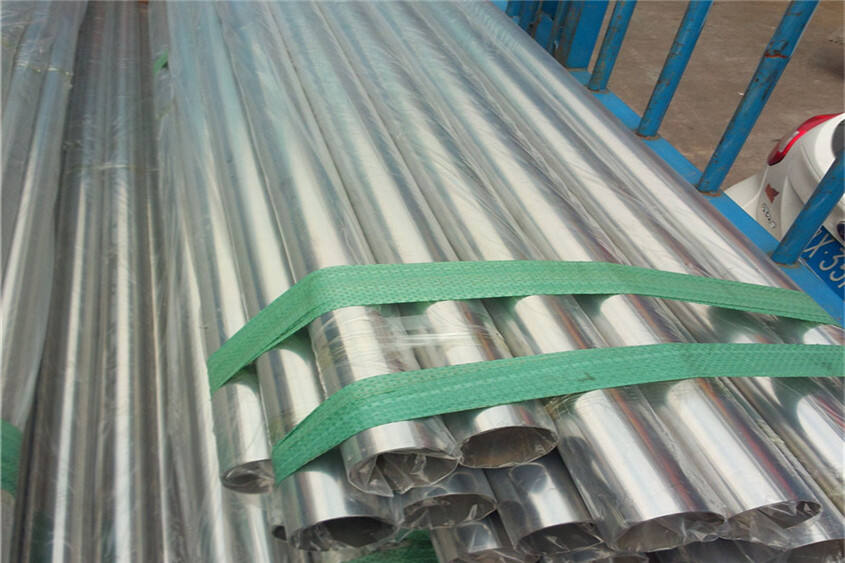

Producenter af rustfrit stålrør anvender state-of-the-art produktionsteknologi, der adskiller dem fra konkurrenter i branchen. Deres faciliteter er udstyret med automatiserede produktionslinjer med præcisionskontrolsystemer, hvilket sikrer konsekvent produktkvalitet og dimensionsnøjagtighed. Avancerede svejseteknologier, herunder TIG-svejsning og lasersvejsning, gør det muligt at fremstille rør med overlegne forbindelsesstyrker og minimale fejl. Produktionsprocessen omfatter systemer til kvalitetsmonitorering i realtid, som kan registrere og løse potentielle problemer, inden de påvirker det endelige produkt. Producenterne anvender også sofistikerede varmebehandlingsfaciliteter, der optimerer rørenes mekaniske egenskaber og sikrer, at de opfylder specifikke ydeevnekrav. Integrationen af computerstøttet produktion (CAM) giver præcis kontrol over produktionsparametre og muliggør effektiv produktionsplanlægning.