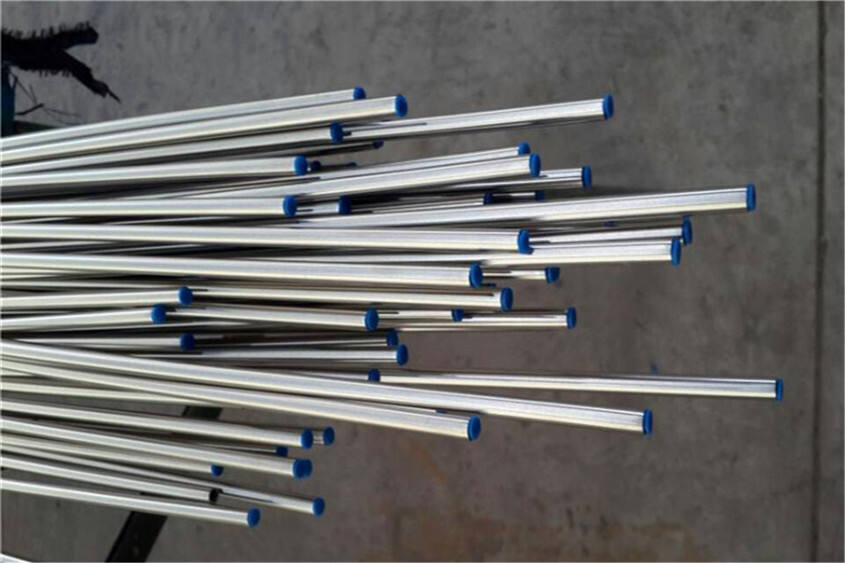

Herausragende Korrosionsbeständigkeit und Dauerhaftigkeit

Das 1 1 2 Edelstahrohr bietet hervorragenden Korrosionsschutz und zeichnet sich dadurch im Industrierohrmarkt aus. Dieses bemerkenswerte Merkmal resultiert aus seiner sorgfältig entwickelten chemischen Zusammensetzung mit optimierten Gehalten an Chrom und Nickel. Die auf der Oberfläche gebildete Passivschicht repariert sich kontinuierlich selbst und gewährleistet so langfristigen Schutz vor verschiedenen korrosiven Umgebungen. Diese inhärente Widerstandsfähigkeit erstreckt sich auf eine Vielzahl von Chemikalien, Säuren und atmosphärischen Bedingungen und macht das Rohr besonders wertvoll für Installationen in Küstenregionen sowie in chemischen Produktionsanlagen. Die Langlebigkeit des Rohrs wird zudem durch seine Widerstandsfähigkeit gegen Lochkorrosion und Spaltkorrosion verstärkt, welche bei weniger robusten Materialien häufig auftreten. Dieser überlegene Korrosionsschutz führt zu geringerem Wartungsaufwand, verlängerten Nutzungsdauern und niedrigeren Gesamtkosten für Endanwender.