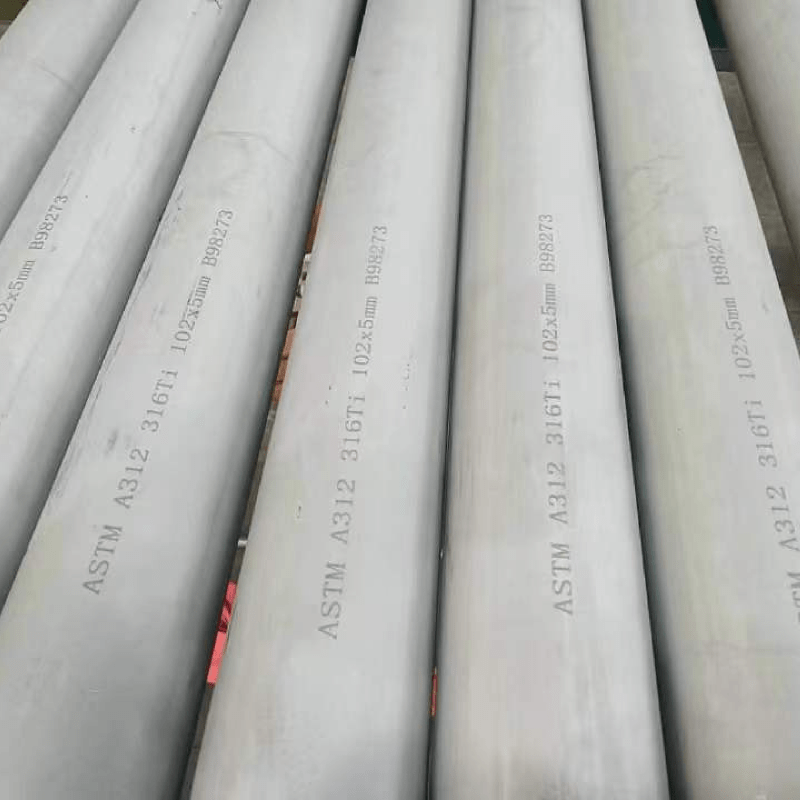

Herausragende Korrosionsbeständigkeit und Langlebigkeit

Der herausragende Korrosionsschutz von Edelstahlrohren und -rohren ist ihre auffälligste Eigenschaft, erreicht durch das Vorhandensein einer Chromoxid-Schicht, die sich bei Beschädigung kontinuierlich selbst repariert. Diese natürliche Schutzschicht macht zusätzliche Beschichtungen oder Behandlungen überflüssig und reduziert dadurch erheblich die Wartungskosten sowie die Lebensdauer. Die Fähigkeit des Materials, aggressiven Umgebungen standzuhalten, einschließlich der Einwirkung von Säuren, Laugen und maritimen Bedingungen, gewährleistet eine gleichbleibend gute Leistung in herausfordernden Anwendungen. Dieser inhärente Schutz vor Zersetzung bewahrt nicht nur die strukturelle Integrität des Systems, sondern erhält auch die Reinheit der transportierten Materialien, was in sensiblen Anwendungen wie der pharmazeutischen Herstellung und der Lebensmittelverarbeitung entscheidend ist. Die langfristige Langlebigkeit führt zu geringerer Austauschhäufigkeit, niedrigeren Lebenszykluskosten und minimalem Wartungsbedarf.