Resistenza alla Corrosione e Durata Superiori

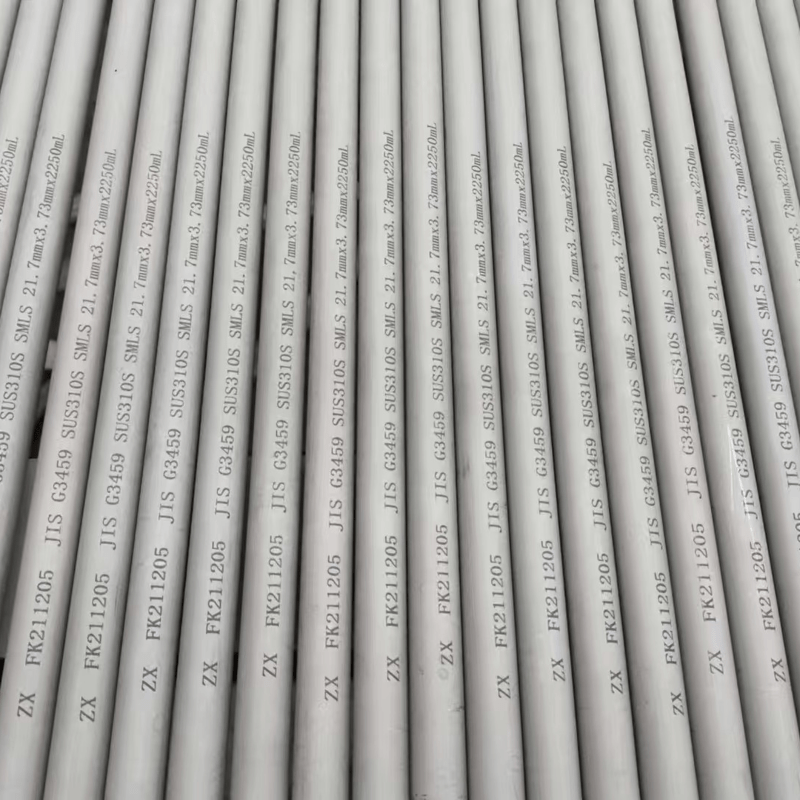

L'eccellente resistenza alla corrosione dei tubi in acciaio inox 1/4 rappresenta una delle sue caratteristiche più significative, in particolare in condizioni ambientali difficili. La composizione chimica del materiale, ricca di cromo e altri elementi leganti, forma uno strato passivo autoriparante che garantisce una protezione continua contro diversi agenti corrosivi. Questa resistenza intrinseca si estende alla corrosione atmosferica, all'esposizione a sostanze chimiche e al degrado causato dall'umidità, assicurando un'affidabilità a lungo termine in svariate applicazioni. La durata del tubo è ulteriormente migliorata dall'elevata resistenza a trazione e da un'ottima resistenza alla fatica, consentendo di mantenere l'integrità strutturale anche sotto condizioni di carico ciclico. Questa combinazione di resistenza alla corrosione e durata riduce significativamente le esigenze di manutenzione ed estende la vita operativa dei sistemi che incorporano questo tipo di tubo, portando infine a costi di ciclo di vita inferiori e a un'affidabilità maggiore.