Превосходная динамика потока

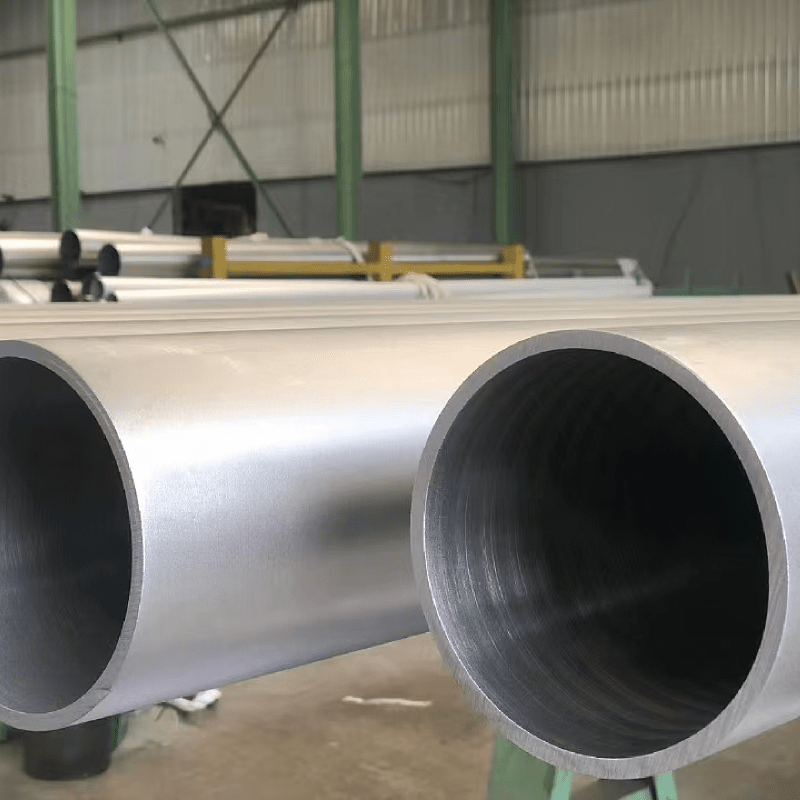

Конструктивная конструкция отводов основана на передовых принципах гидродинамики для оптимизации характеристик потока. Тщательно рассчитанный радиус кривизны минимизирует турбулентность и снижает потери давления, обеспечивая эффективную транспортировку жидкости при изменении направления. Эта особенность особенно важна в высокопроизводительных системах, где поддержание стабильности потока имеет решающее значение. Гладкая внутренняя поверхность с шероховатостью менее 2 микрометров значительно снижает трение и предотвращает образование завихрений, нарушающих поток. Такой подход к проектированию внутренней геометрии позволяет снизить перепад давления на 30% по сравнению со стандартными фитингами, что позволяет снизить энергозатраты и эксплуатационные расходы.