Herausragende Korrosionsbeständigkeit und Dauerhaftigkeit

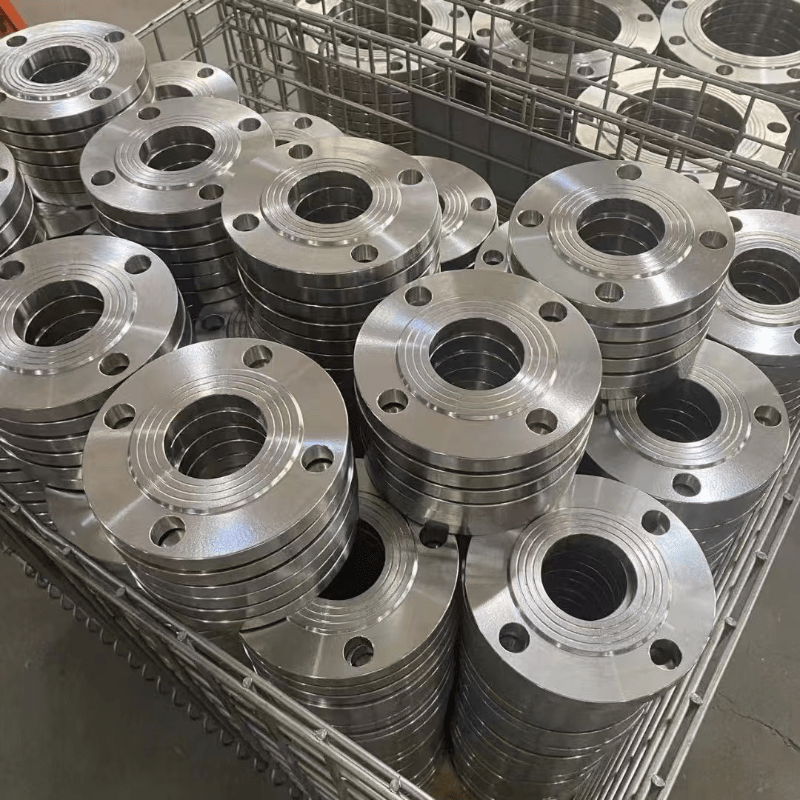

Edelstahl-Flansche zeichnen sich durch hervorragende Korrosionsbeständigkeit aufgrund ihrer chromreichen Zusammensetzung aus, wodurch sich eine selbstheilende Passivschicht bildet, die kontinuierlichen Schutz vor Oxidation und chemischen Angriffen bietet. Diese inhärente Eigenschaft gewährleistet langfristige Zuverlässigkeit in aggressiven Umgebungen, einschließlich Kontakt mit Säuren, Laugen und Salzwasser. Die Fähigkeit des Materials, unter verschiedenen chemischen Bedingungen seine strukturelle Integrität beizubehalten, macht es ideal für Anwendungen in der chemischen Verarbeitung, Offshore-Anlagen und Wasserbehandlungsanlagen. Die Langlebigkeit von Edelstahl-Flanschen führt zu einer geringeren Austauschhäufigkeit und niedrigeren Wartungskosten und bietet Betreibern erhebliche langfristige Kostenvorteile.