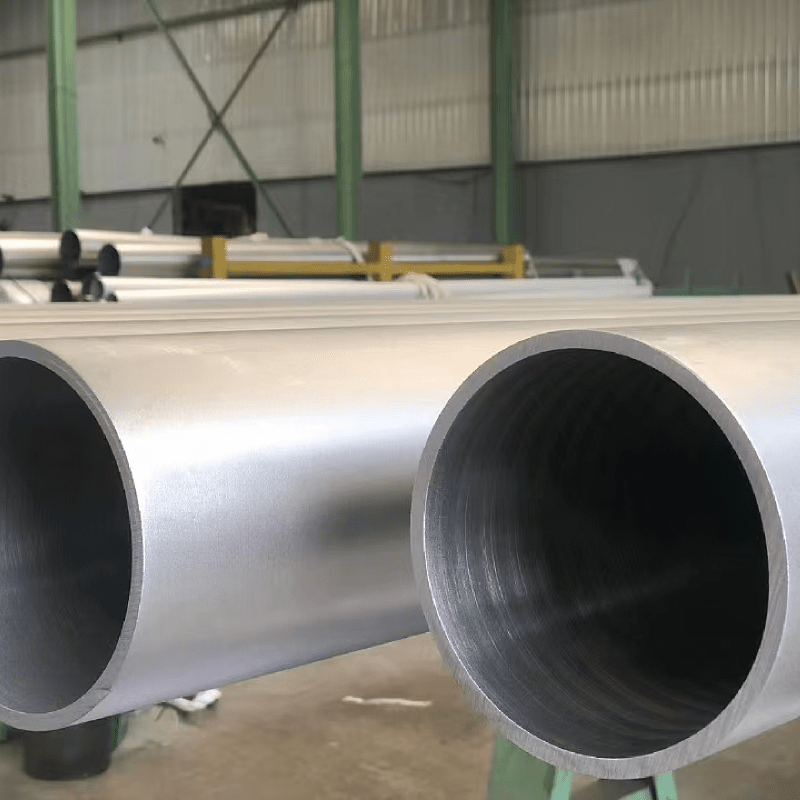

Superior Material Composition and Durability

The exceptional durability of stainless steel pipe fittings stems from their carefully engineered material composition. The primary grades used, 304 and 316 stainless steel, contain specific proportions of chromium and nickel that create a self-healing passive layer, providing outstanding protection against corrosion and oxidation. This passive layer automatically regenerates when damaged, ensuring continuous protection throughout the fitting's service life. The material composition also contributes to excellent mechanical properties, including high tensile strength and hardness, enabling these fittings to maintain structural integrity under various pressure and temperature conditions. The addition of molybdenum in grade 316 further enhances resistance to pitting and crevice corrosion, particularly in marine and chloride-rich environments.