Doskonała dynamika przepływu i efektywność

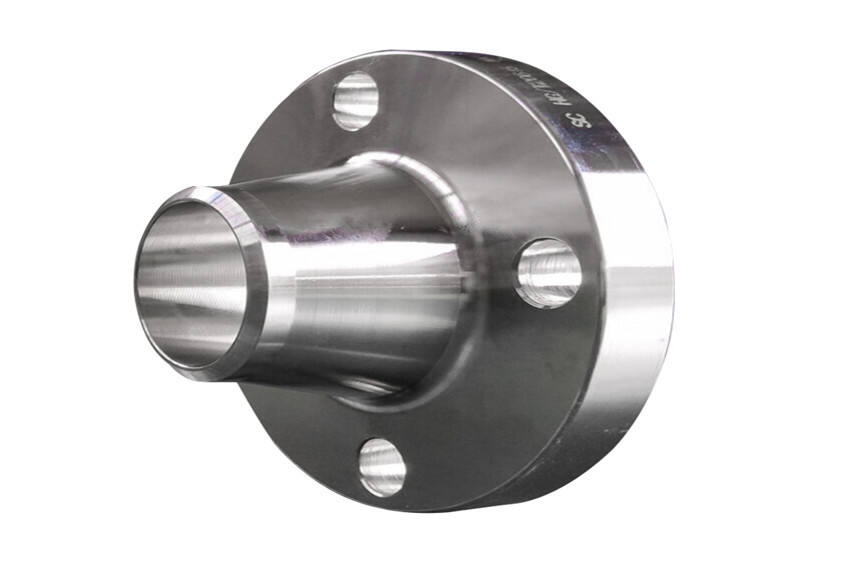

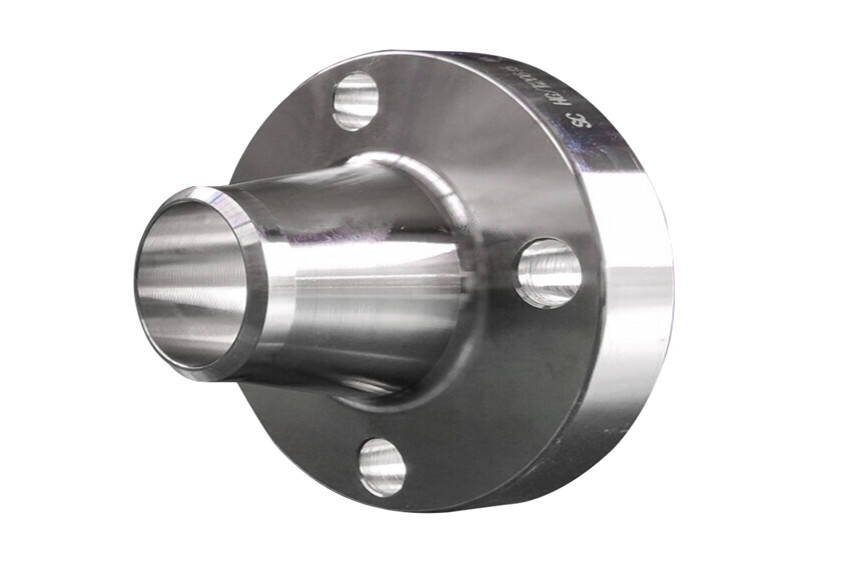

Zaprojektowana konstrukcja kolank rur rewolucjonizuje zarządzanie przepływem cieczy poprzez zastosowanie zaawansowanych zasad hydraulicznych. Gładka, ciągła krzywa utrzymuje laminarny charakter przepływu, znacząco redukując turbulencje i straty energetyczne w porównaniu z rozwiązaniami segmentowymi. Optymalny charakter przepływu przekłada się na niższe zapotrzebowanie na moc pomp oraz obniżone koszty eksploatacyjne. Jednolita powierzchnia wewnętrzna zapewnia stałą prędkość przepływu płynu przez cały zakręt, uniemożliwiając lokalne wahania ciśnienia, które mogłyby prowadzić do erozji lub kawitacji. Ta cecha jest szczególnie ważna w zastosowaniach o dużym przepływie, gdzie utrzymanie sprawności przepływu ma kluczowe znaczenie dla wydajności systemu. Starannie obliczony promień krzywizny minimalizuje straty związane z tarciem, jednocześnie gwarantując integralność strukturalną, co czyni te kolanka idealnym wyborem zarówno dla zastosowań wysokociśnieniowych, jak i o dużej prędkości przepływu.