Передовые производственные технологии

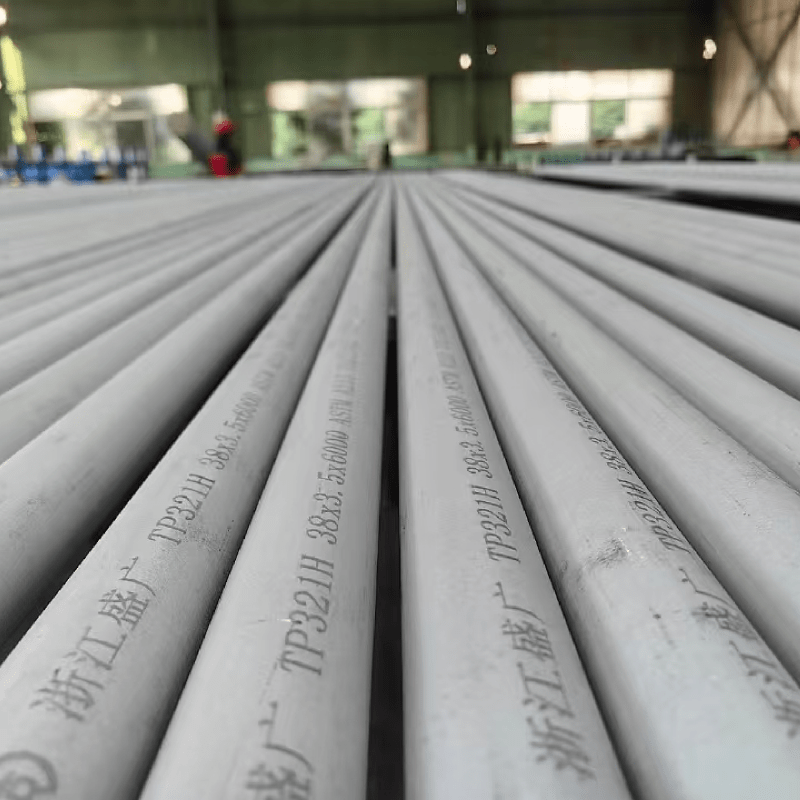

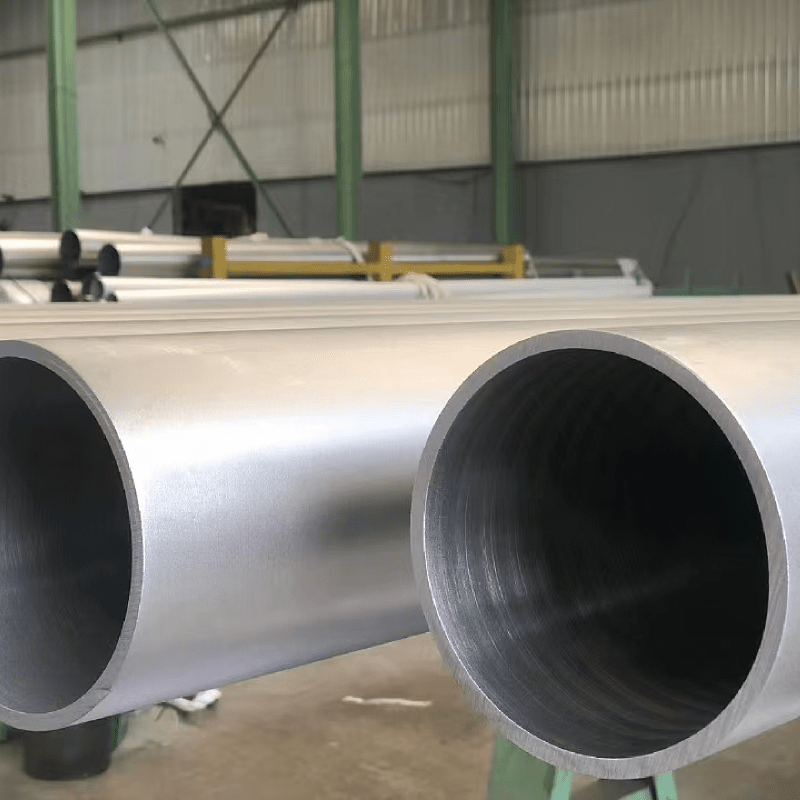

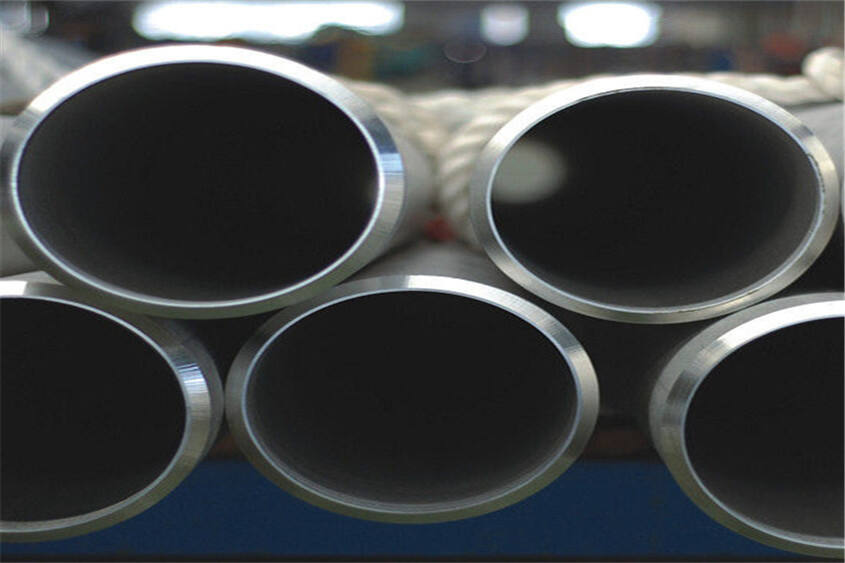

Современные производители нержавеющих стальных труб используют передовые технологии производства, которые выделяют их на фоне конкурентов в отрасли. Их производственные мощности оснащены автоматизированными сварочными системами с точным контролем, обеспечивающими стабильное качество сварных швов и структурную целостность. Современные прокатные станы, оснащённые компьютеризированными системами управления, достигают точных размерных допусков и обеспечивают высококачественную поверхность. Эти производители применяют сложные процессы термической обработки, оптимизирующие механические свойства труб, повышая их долговечность и эксплуатационные характеристики. Интеграция систем контроля качества в режиме реального времени на всех этапах производства позволяет немедленно выявлять и устранять любые отклонения от заданных параметров. Эти технологические достижения распространяются и на системы транспортировки материалов, предотвращающие повреждение поверхности во время производства и хранения.